| Installation of your Unobtainium Motorsports differential mount kit is

fairly straight forward. Please refer to the illustration above

and in the body of these instructions in order to simplify the identification of

the parts in your kit and their installed locations. |

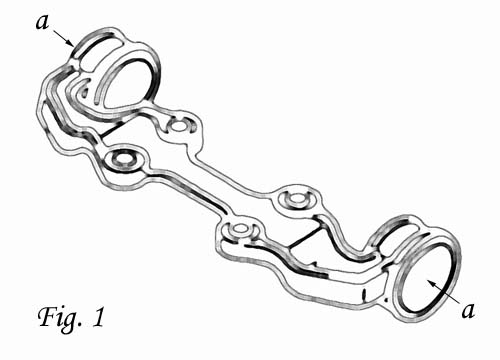

| 1. Refer to the Mazda 3rd

generation RX-7 Shop Manual for instructions on the removal and replacement of

the differential mount.

Torque values for the differential mount bolts and nuts will be listed in the

shop manual. Please follow those instructions precisely to ensure

correct installation of the differential mount. 2. Once the differential mount has been removed from the car, use a hydraulic press to press out the OEM rubber bushings, or have a machine or suspension shop perform this service for you. 3. The center pins in your kit are intended to be a loose fit and will not be installed with the nylon bushings when they are pressed into the differential mount. Set the center pins aside, since they will not be installed until you are ready to replace the differential mount on the vehicle. 4. There are two large bushings in the differential mount kit, shown in Fig. 3 below. Their position is illustrated in Fig. 1 above as a, one bushing for each side of the differential mount. Press the bushings into the differential mount in position a in the direction of the arrows in Fig. 1 above, so that the flanged ends of the bushings face outward, in the opposite direction of the arrows.

5. Once both bushings have been installed,

follow the Mazda Shop Manual instructions for replacement of the differential mount.

Before installing the bolts which hold the differential mount on the car, coat the

outside surface of the stainless steel center pins (shown in Fig. 3 below)

with anti-seize lubricant,

and slide them into the centers of the nylon bushings, wiping off any excess. Again,

the center pins are designed to be a loose fit and should slide and

rotate freely within the nylon bushings.

6. Once the center pins are installed in

the nylon bushings, you can reinstall the differential mount on the car. It is your

choice whether or not to coat the

bearing surface (non-threaded area) of each bolt which passes through a stainless

steel center pin with anti-seize lubricant. While this step is not absolutely

necessary, we do recommend it. Install the bolts which attach the differential

mount to the rear subframe and the nuts which attach the mount to the differential

following Mazda's torque specifications precisely to ensure a correct

installation. 7. Installation of the differential mount

bushings does not require having the car realigned, but if you have replaced any of

the other suspension bushings at the same time, we highly recommend having the

suspension aligned

by a professional suspension shop in order to ensure that your suspension geometry

is correct. 8. Congratulations! You now have the highest

performance differential mount bushings money can buy on your RX-7, and you should

feel a night-and-day difference

in the reaction of the car to throttle input when compared to the OEM rubber

bushings. |

Note: This page reproduced with the kind permission of

Unobtanium Motorsports.

| THE LEGAL STUFF: Unobtainium Motorsports products are intended for off-road use ONLY. Unobtainium Motorsports makes

no claims as to the legality of use of these products on a licensed vehicle used on public roads or highways. Unobtainium Motorsports

is not responsible for any damage to the vehicle caused by improper installation or improper use of the product or vehicle by the customer or any other party.

Damage to the product caused by improper installation or use is not covered by any warranty, either express or implied. Product warranty

is limited to manufacturing defects only. Unobtainium Motorsports will replace any defective product at our discretion, once the part has been received

and inspected, and the cause of the failure has been determined to be a manufacturing defect. Unobtainium Motorsports HIGHLY recommends that our products be installed only by trained professionals, and especially with any suspension modifications, that the vehicle manufacturer's service procedures and recommended torque figures be strictly adhered to. In addition, we recommend that the vehicle's alignment be checked and corrected, if necessary, after removal or replacement of any suspension related components. And finally, we highly recommend that any components removed from the vehicle be inspected by a professional service representative prior to being replaced, and if any component or fastener is found to be damaged or substandard in any way, that it be replaced immediately with a new part. Failure to follow these recommendations may result in loss of property or serious injury. |

Date: Thu, 13 Mar 2003 20:29:40 -0000

From: "rx712psi" (rx712psi@yahoo.com)

Subject: Re: (rx7) [3] diff bushings/HOW TO

That was me that said you could just remove the D-shaft & PPF then rotate the diff until the input shaft is pointing down. It actually doesn't need any support as there are already rubber axle rests somewhere back there that keep the diff from just falling (been a while so I don't remember exactly where).

I re-used all of the nuts & bolts.

I actually wrote up & posted a how to over a year ago:

INSTALL HOW TO:

[disclaimer] this message outlines what I remember from removal & installation of the Differential mount on my 93 Touring model. If you are not experienced with mechanics or firmly supporting a vehicle on jackstands then I suggest you do not attempt to perform this operation!

Tools needed:

Air compressor 3/8 Air Impact wrench 3/8 Air Ratchet (optional) 3/8 shorty Ratchet 3/8 3" extension 3/8 6" extension 3/8 10mm Socket 3/8 12mm Socket 3/8 14mm Socket 3/8 17mm Socket 1/2 21mm Deep Socket 1/2 Ratchet 1/2 6" extension 5 jackstands Nice floor jack Zip Ties

________________

Date: Fri, 14 Mar 2003 07:25:50 -0500

From: "Newbern, David" (David.Newbern@telenor-usa.com)

Subject: RE: (rx7) [3] diff bushings/HOW TO

That seems like way more with that I did.. I replaced the bushings without pulling the PPF, without pulling the driveshaft, withouth pulling any parts. I think I undid the rear exhaust, unbolted the diff by reaching around to the top with a box wrench (and a lot of swearing) and just dropped it down.. you only get a few inches of clearance, but you only need a few inches. No need to take apart the whole car.