By Shiv Pathak

Photography by Les Bidrawn, Dave Coleman

In the last installment of Project RX-7 (SCC, Jan. '99) we focused on vital maintenance

issues as well as several important reliability-related upgrades. Among them, we installed

a Blitz turbo timer, and boost and fuel pressure gauges from Auto Meter. Additionally,

Mostly Mazda secured the "rat's nest" of vacuum lines which lie under the intake manifold

with small tie wraps. They also replaced the often ignored fuel filter that has proven to

be a single point of failure for many unfortunate RX-7s.

In the last installment of Project RX-7 (SCC, Jan. '99) we focused on vital maintenance

issues as well as several important reliability-related upgrades. Among them, we installed

a Blitz turbo timer, and boost and fuel pressure gauges from Auto Meter. Additionally,

Mostly Mazda secured the "rat's nest" of vacuum lines which lie under the intake manifold

with small tie wraps. They also replaced the often ignored fuel filter that has proven to

be a single point of failure for many unfortunate RX-7s.

So what's next? While increasing engine output may be tempting, it may not be the best idea at this stage in our project. Why not? As we have seen during preliminary evaluations at Thunderhill Raceway, we have already brushed upon the limits of the car's stock cooling system and brakes. According to our RX-7 guru, Brian Richards of Mostly Mazda, increasing horsepower levels may potentially excascerbate our problem.

"The more horsepower the little rotary produces, the more heat it generates. If we're already pushing the cooling system with 255 ponies, increasing output 50 to 60 percent would likely make things worse. Furthermore, if the car already suffers from severe brake fade during repeated braking from 110 mph on the long straight, it certainly couldn't handle braking from 130 mph." We agree. Increases in engine output will have to wait until we have the braking and cooling system problems under control.

Big Brakes are NOT for Wussies

Big Brakes are NOT for Wussies

According to Brian, the stock brakes prove to be exceptional performers for street use.

Blessed with relatively large 11.6-inch ventilated rotors at each corner, and beautifully

crafted, lightweight, aluminum four piston calipers up front, the RX-7 stops with

impressive authority. Many well known automotive scribes have suggested that only a

handful of high-performance exotics can match or exceed the stopping performance of the

third generation RX-7. Certainly not a bad place to start.

If others find the brakes so remarkable, why do we have problems? Simply put, we are driving the snot out of the car. Much like real road racing, we are evaluating the car under severe (and prolonged) conditions. Thunderhill is no autocross. We are not hustling the car between cones for 50 seconds at a time in a parking lot. Instead we are running at or near wide open throttle on a high-speed road course for sessions lasting as long as 30 minutes. During prolonged high-speed track evaluations, heat is generated faster than it is shed. Eventually, brake components get too hot and we see fade. Unfortunately, brake fade is a fact of automotive life. Every car, from an exotic Formula One racer to a mega-buck British Touring Car, is plagued with brake fade to a certain extent. The goal in any serious brake system is to control this problem.

According to Brian, there are several ways we can control brake fade. The most common

and cost effective method is a simple brake pad upgrade. While Mazda has invested

gratuitous sums of money in the development of the RX-7's brake pads, they are designed to

meet the expectations of most "typical" consumers (low wear rates, cold friction, noiseless

operation). Unfortunately, we are anything but "typical". As shameless speed freaks, we

have our own set of warped expectations.

According to Brian, there are several ways we can control brake fade. The most common

and cost effective method is a simple brake pad upgrade. While Mazda has invested

gratuitous sums of money in the development of the RX-7's brake pads, they are designed to

meet the expectations of most "typical" consumers (low wear rates, cold friction, noiseless

operation). Unfortunately, we are anything but "typical". As shameless speed freaks, we

have our own set of warped expectations.

There are several high-performance brake pads available in the aftermarket. These highly specialized pads are designed to withstand the heat of heavy road racing. Furthermore, they often are less expensive than their OEM counterparts. However, this approach is not without compromise. Race pads typically don't work when cold. In fact, a few hard laps on the track are often needed to get them up to operating temperatures. Another characteristic of race pads is their tendency to shed copious amounts of dust all over the wheels and the quarter panels. Most unfortunate however, is their tendency to "chew up" rotors. Needless to say, these characteristics severely limit their "daily driving" appeal.

As we have established, our goal (and challenge) in the Project RX-7 series is to dramatically improve racetrack performance, while accepting no (or very little) compromise in streetability. As an honest-to-gosh daily driver, we need race-ready brakes that will also work first thing in the morning and not squeal loud enough to compete with local air traffic. Can this be done? Let's find out.

Automatically, our first upgrade to the brake system was replacing the stock rubber brake lines with inflexible stainless steel lines. Eliminating any possible expansion of the lines under hard braking was bound to result in a noticeably stiffer pedal. No such luck. With some imagination and a nice foot massage between tests, we might be able to convince ourselves of a firmer pedal. Brian was quick to point out that the stock brake lines are already incredibly stiff by most standards and little, if any, was to be gained by "upgrading" them. "If you just had to spend the $120, that's fine. It's certainly better than spending the money on a pretty faux carbon-fiber shift-knob," he remarked. Our next upgrade involved installing an appropriate brake pad. A popular streetable pad that might work fairly well on the track is the Hawk HPS (High Performance Street) pad. Priced less than the unreasonably expensive OEM pads, we owed it to ourselves to try them before we approach far more dramatic (and costly) alternatives. Once installed, we properly "bedded" them as per the manufacturer's directions. Compared to the stock pads, the Hawks provided very different braking performance. When cold, they were extraordinarily "grabby" and required much less pedal pressure. This unusually sensitive braking behavior often made threshold braking slightly more difficult. Proper heel/toe downshifts also proved to be more troublesome since slight changes in brake pedal pressure (while one "blips" the throttle with the right edge of his foot) would often make braking a bit choppy.

As we learned during our track evaluation, the Hawk's "hyper-sensitivity" to pedal

pressure was only apparent on the street when the pads remain relatively cold. When the

car was driven at Thunderhill Raceway, the brakes would heat up and become much more

progressive and predictable. The HPS pads also held up surprisingly well (for nearly three

hard laps) before any hints of fade. And fade they did. By the fourth lap, the braking

zones approaching Turn 1 had to be advanced by several car-lengths. Nevertheless, they did

handle the heat appreciably better than the stock pads which would have faded well before

the third lap. As an added bonus, the Hawks also proved to be very gentle on the rotors.

While the Hawk pads did emit more dust (and smell) than the stockers, it was well within

the limits of what most enthusiasts would consider acceptable. However, it was clear that

the Hawk HPS pads, while likely to be perfectly suited for autocrossing, did not meet our

needs on the race track. Once again, the guys at Mostly Mazda Racing were not surprised.

Another popular alternative is having two sets of rotors and pads, one for the track and

one for the street. On the track, where cold stopping and noise aren't an issue, we could

use Hawk's "race only" Blue pads on an extra set of dedicated rotors. Why a dedicated set

of rotors? Because race-only pads contain more heat-resistant ingredients (such as

Kevlar) that tend to chew up rotors. While the extra set of rotors is surprisingly

affordable, and not very difficult to remove and install (especially when one is already

swapping brake pads), our project goals necessitate a more elegant solution. We want to

have our cake and eat it too. Is that too much to ask? To get answers to this question, we

drove Project RX-7 350 miles due south towards Lawndale, Calif. to pay a visit with

Cooltech Automotive LLC.

As we learned during our track evaluation, the Hawk's "hyper-sensitivity" to pedal

pressure was only apparent on the street when the pads remain relatively cold. When the

car was driven at Thunderhill Raceway, the brakes would heat up and become much more

progressive and predictable. The HPS pads also held up surprisingly well (for nearly three

hard laps) before any hints of fade. And fade they did. By the fourth lap, the braking

zones approaching Turn 1 had to be advanced by several car-lengths. Nevertheless, they did

handle the heat appreciably better than the stock pads which would have faded well before

the third lap. As an added bonus, the Hawks also proved to be very gentle on the rotors.

While the Hawk pads did emit more dust (and smell) than the stockers, it was well within

the limits of what most enthusiasts would consider acceptable. However, it was clear that

the Hawk HPS pads, while likely to be perfectly suited for autocrossing, did not meet our

needs on the race track. Once again, the guys at Mostly Mazda Racing were not surprised.

Another popular alternative is having two sets of rotors and pads, one for the track and

one for the street. On the track, where cold stopping and noise aren't an issue, we could

use Hawk's "race only" Blue pads on an extra set of dedicated rotors. Why a dedicated set

of rotors? Because race-only pads contain more heat-resistant ingredients (such as

Kevlar) that tend to chew up rotors. While the extra set of rotors is surprisingly

affordable, and not very difficult to remove and install (especially when one is already

swapping brake pads), our project goals necessitate a more elegant solution. We want to

have our cake and eat it too. Is that too much to ask? To get answers to this question, we

drove Project RX-7 350 miles due south towards Lawndale, Calif. to pay a visit with

Cooltech Automotive LLC.

Cooltech has been designing and manufacturing state-of-the-art braking systems since 1995. Initially, Cooltech worked exclusively on high-performance European exotics, including Ferraris, Lamborghinis and Porsches. More importantly, Cooltech has also been heavily involved in IMSA race car projects that compete in various endurance races like the 24 Hours of Daytona. Luckily for the rest of us, soon after being acquired by Advanced Engine Management (AEM) in 1998, Cooltech entered the ever-growing import aftermarket. Using components from Brembo, as well as its proprietary products, Cooltech is quickly becoming a popular name with road racing enthusiasts. I spoke with the president of Cooltech, Jeff Hays, about the importance of braking performance as well as his unique approach to developing braking systems.

The Physics of Braking

Jeff is a quiet, understated man who truly appreciates good brakes. As a road racer with

12 years of experience, he knows that a superior braking system will provide a tremendous

advantage over the competition. "On the track, cars are too evenly matched in horsepower

to be able to accomplish a clean pass in the straights. Instead, most successful passes

occur in the heavy braking zones before turns. The passing car is usually on the inside

of the turn and is able to go deeper before braking. If he can slow down enough, stay on

the track, and drive a good line through the turn and pull off a fast exit, he will get in

front. While it is easier said than done, braking performance is crucial to winning races."

We couldn't have said it better ourselves.

"So Jeff," I asked, "Can we have a no-compromise braking system designed for road racing that is also truly usable on the street?" Without hesitation and with a proud, mischievous grin, he replied, "Definitely. Let's get the car on stands, look at the stock brakes, take some measurements and see how obsessive we can be about an upgrade." Who are we to argue with that kind of attitude?

Within minutes, Hays and his crew were scrutinizing the stock brakes on our RX-7. Immediately, Hays was impressed with Mazda's work. From the factory, the RX-7 uses nicely machined, lightweight aluminum calipers instead of heavy iron units typically found in many far more expensive performance cars. The 11.6x0.85-inch iron rotors are also quite good. For a car that weighs less than 2,800 lbs, the swept area the rotors and pads provide is impressive by OEM standards. Nevertheless, Hays assures me that there is plenty of room for improvement.

Before we start on our car, we should investigate the physics behind braking. Brakes are relatively simple devices which convert kinetic energy into heat. As the pads apply pressure on a moving rotor, heat is transferred into the rotor as well as into the pads. As the act of braking continues, heat will accumulate in these various components. If heat is transferred to the braking system faster than it is shed into the surrounding air, something will eventually fail.

According to Hays, there are two types of brake failure often experienced on the race track. One type, as we encountered firsthand, is caused by brake pads which can eventually overheat. No problem, we did just fine with race pads, right? Not quite. While our quick and easy solution was effective, it only works up to a certain point. While the race pads will thrive on these extremely high temperatures, the other braking components are not as tolerant. The laws of physics dictate that the iron rotors can only contain a finite amount of heat. Once they have reached their maximum heat capacity (known as "heat soak"), heat will travel up the system and eventually boil the brake fluid. Once brake fluid starts to boil, all the pressure your foot places upon the brake pedal goes into crushing the tiny bubbles in the fluid, rather than squeezing the pads against the rotors. As an unfortunate result, the brake pedal slams against the floorboard, the owner screams colorful profanities, the vehicle plows off the track, and the structural integrity of its fenders are tragically compromised.

OK, so brake pads can only take us so far. Hays, as always, has an answer. "The next logical upgrade after a simple brake pad swap is installing a larger rotor. Since bigger rotors are heavier, they are able to store more energy before becoming heat soaked. This will always reduce brake fade. Furthermore, large rotors offer far more overall surface area and are able to shed heat faster. Monstrous rotors also provide a distinct mechanical advantage during braking. Clamping down on the edge of a 13-inch rotor is far more effective than doing so on a 9-inch rotor. To ensure proper fit, larger calipers are almost always necessary when dramatically increasing the diameter of rotors." However, as Hays is quick to point out, installing larger rotors does have its drawbacks. Unfortunately, iron is not light. In fact, each of the RX-7's 11.6-inch rotors weighs nearly 15 lbs. Now, let's say we wanted to mount a set of extra beefy, 12.7-inch rotors typically found on perhaps the best braking production car in the world, the Porsche 911 Turbo.

While the bigger rotors would be able to stop the car in a shorter distance and be more able to withstand the rigors of the race track, they also weigh a whopping 21 lbs each. An extra 6 lbs per rotor does not seem like a big deal at first glance. However, it is important to realize that rotors (and wheels, tires and hubs) are rotating mass, so not only do we have to deal with accelerating them in a straight line, we also have to accelerate their rotational speed. In the case of round objects such as rotors, rotational inertia increases with the square of the radius. In other words, mass furthest from the center of rotation (in this case, the wheel hub) has a far greater inertial effect than mass close to the center of rotation. For big, heavy rotors that evenly spread their mass from the hub to almost the inner edges of the wheel rim, 6 extra lbs, according to Hays, is approximately equivalent to a 24 lb of static mass. Multiply again by four (for each corner of the car), and you are looking at a 96 lb increase in effective weight. For a car that Mazda went to nearly ridiculous lengths to minimize weight; adding nearly 100 lbs would certainly be a pity. Furthermore, this extra mass is un-sprung, meaning that it moves up and down with irregularities of the road surface. As all automotive engineers know, increasing un-sprung weight greatly compromises the suspension's ability to do its job. So how do we improve braking performance without sacrificing handling, ride quality, and un-sprung weight?

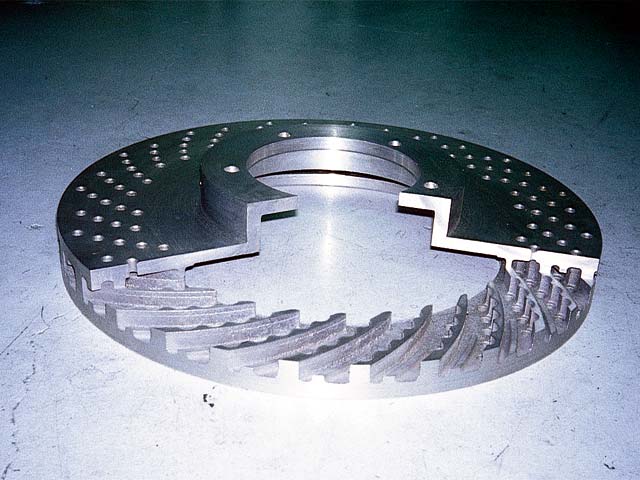

Fortunately for us, Cooltech has a very unique solution. Instead of using iron rotors for its top-of-the-line braking systems, it uses a remarkable material known as Metal Matrix Composite, or MMC for short. According to Hays, MMC rotors (Cool Rotors) provide several advantages compared to traditional rotors.

Reduction of Rotating and Un-Sprung Weight

MMC rotors are roughly one-third the weight of traditional gray iron rotors. As a direct

result, handling, ride quality and even acceleration performance is improved.

"Another popular alternative is having two sets of rotors and pads, one for the track and one for the street"

Increased Rotor Life

Although exceptionally light, the ceramic composite nature of its construction make MMC

far stronger and more wear resistant than iron. According to Cooltech, MMC rotors will

easily last the life of the car under normal use and will never have to be "turned"

(machined on a lathe). We understand they are less prone to crack or warp like an iron

rotor when subjected to sudden changes of extreme temperatures.

Increased Cooling

Depending on operating temperatures, the thermal conductivity of MMC is up to five times

greater than iron. This means that MMC rotors are able to shed heat quickly and be more

resistant to brake fade. Also, since the rotors operate in cool temperatures (hence the

name Cool Rotors), brake pads last significantly longer. More impressively, they function

perfectly well first thing in the morning when they are bone cold.

MMC is still forced to abide by the laws of physics. Due to its low mass, it is not able to store as much heat as heavy iron rotors. However, its low mass does allow exceptionally large rotors which, in turn, offer more surface area to dissipate heat into the surrounding air. Coupled with the dramatically improved thermal conductivity, MMC rotors rarely experience full heat soak.

So MMC rotors offer enhanced braking, better cooling, vastly improved durability, and serious weight advantages. What's the catch? Cost. MMC is expensive to machine and manufacture. As a result, Cool Rotors demand a 15 to 20 percent price premium over iron rotors. Not an unreasonable expense, of course, considering the inherent benefits provided by MMC. In fact, Chrysler uses MMC rotors with its Prowler hot-rod as does as Lotus for its high-performance, ultra-lightweight Elise sports car.

Hays measured the RX-7's big 17-inch Volk Racing wheels and determined that he could fit

an enormous 14x1.15-inch rotor behind it with no interference problems. Fourteen inch? I

was a bit skeptical but I kept my mouth shut. The rest of the guys at Cooltech were busy

machining adapter hats and brackets out of aluminum. Hours later, once machined to precise

tolerances and anodized black, the exquisite aluminum hat was bolted to the center of the

rotor and test fitted on the front hubs. Fit like a glove. Since the cool rotors are

crossed drilled (well, actually the holes are cast in) and impervious to warping or

cracking, the stock metal splash shield behind the rotor was deemed unnecessary and

removed to maximize cooling, and to shave off a little weight. Speaking of weight, the

unreasonably large front rotor assembly weighed in at a mere 7.65 lbs--almost half the

weight of the toyish-looking stock rotors.

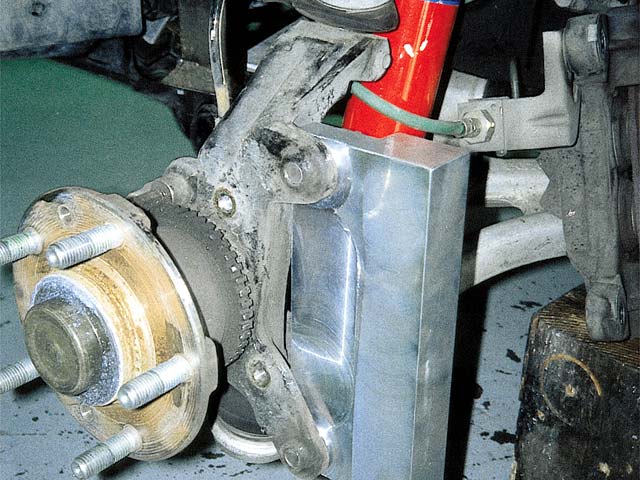

Hays measured the RX-7's big 17-inch Volk Racing wheels and determined that he could fit

an enormous 14x1.15-inch rotor behind it with no interference problems. Fourteen inch? I

was a bit skeptical but I kept my mouth shut. The rest of the guys at Cooltech were busy

machining adapter hats and brackets out of aluminum. Hours later, once machined to precise

tolerances and anodized black, the exquisite aluminum hat was bolted to the center of the

rotor and test fitted on the front hubs. Fit like a glove. Since the cool rotors are

crossed drilled (well, actually the holes are cast in) and impervious to warping or

cracking, the stock metal splash shield behind the rotor was deemed unnecessary and

removed to maximize cooling, and to shave off a little weight. Speaking of weight, the

unreasonably large front rotor assembly weighed in at a mere 7.65 lbs--almost half the

weight of the toyish-looking stock rotors.

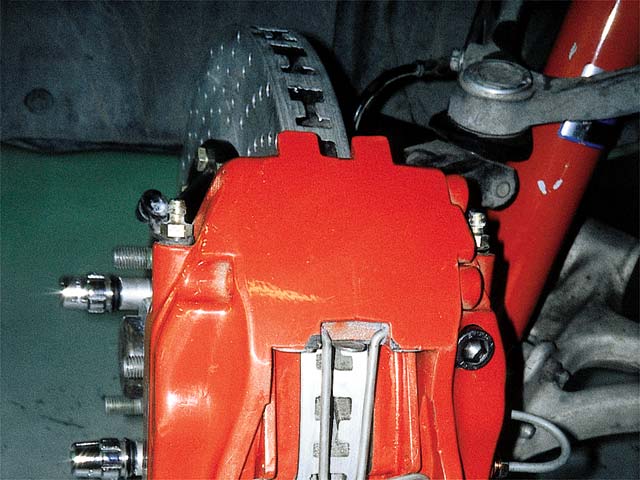

In parallel, another kind gentleman at Cooltech was busy carefully machining aluminum brackets for the new Brembo four-piston caliper (that can be found behind the rear wheels of a Porsche 911 Twin Turbo). The large aluminum Brembo caliper (with bracket) weighed in at 9.45 lbs (compared to 6.20 lbs for its stock counterpart). Once the rotors were fitted and the new adapter brackets were secured to the shiny red calipers, the assembly was simply bolted to the stock hubs. Hays gracefully slid a fresh pair of Cooltech's own special proprietary brake pads (known as Cool Pads, of course) in each caliper. After quickly bleeding the system and checking for leaks, the front brakes were finally done. We eagerly mounted the wheels. Perfect fit. Hays, although relieved, was not surprised. I, on the other hand, was emotionally moved. With fist clenched, I stood in a testosterone-induced frenzy, silently appreciating the vision of magnificence which stood before me. My prolonged moment of passion was interrupted by a polite, soft-spoken suggestion that I take it for a gentle test drive. Without hesitation, Hays and I bounded into the car and headed to the street. "Go easy on them at first, and don't be surprised if the brakes initially produce some mild smoke for the first drive," Hays warned, "That's just the pads burning off some topical resin and oils." Gentle I was and smoke they did. Although I had to refrain myself from bonzai, no-holds-barred threshold braking for a few days, I immediately felt a difference in pedal feel. Offering almost no pedal travel and requiring high pedal efforts, the braking felt much like a real, honest race car. Very nice. So nice, in fact, that we decided to leave the rear brake upgrade for another project installment. For now, we will evaluate the effects of upgrading only the front brakes (which most available brake upgrade kits are designed to do anyway).

Cooling the Cooling System

Unfortunately, we still can't flog the car on the racetrack until we address the other

major problem we have been experiencing--overheating. While usually adequate for normal

driving, the RX-7's cooling system is inadequate for prolonged road racing. Brian Richards

reports that many of his customers have had good experiences with the radiator upgrade he

offers (a Mazda Competition unit). However, there have been a few complaints about its

difficulty of installation. Apparently, minor cutting and trimming of the radiator brackets

are involved. To learn more about this upgrade, we went straight to the manufacturer,

Anthony Woodford Racing in Vista, Calif. (Before you start trying to track them down, note

that all the AWR parts on our project car are available through Mostly Mazda/M2

Performance.)

Anthony Woodford has been responsible for many successful projects with Mazda Motorsports, including a rotary engine conversion for Formula Atlantic race cars as well as a Mazda Protege road race package for SCCA racing. In fact, the Mazda rotary-powered Formula Atlantic car recently won the '98 Southern Pacific Division Championships, while a Protege ES came first in its class in the Northern Pacific Divisional Championship. That same Protege also won the '98 SCCA Runoffs in Mid-Ohio. AWR has also been involved in Protomotive Racing's Mazda Miatas which have been competing in the Speedvision Cup series. For nearly four years, AWR has been working closely with Mazda Competition parts, developing and manufacturing everything from radiator upgrades to brake cooling ducts (which we already have our greedy eyes on).

His third generation RX-7 radiator upgrade is a beautiful piece of work. Unlike the stock radiator which has plastic end tanks, AWR's replacement is all-aluminum. Besides having roughly 50 percent more capacity (by using two rows of fins instead of one), it also incorporates a fin design that offers improved heat dissipation. To keep this fair, we re-used the very same coolant for the new radiator. We did, however, need to compensate for the extra capacity with a 50/50 mix of water and coolant.

Was there any fitting involved in the installation after all? Yes, some fitting was definitely required. However, Woodford has documented every single necessary snip and cut, and every new batch will incorporate these changes. The installation procedure described in Mazda's workshop manual (which all RX-7 owners should have) will finally also apply to Mazda Competition's radiator upgrade. Unfortunately, the scope of this project prohibits us from offering in-depth installation instructions. You should refer to the workshop manual for step-by-step documentation.

While the car was on jack stands, Woodford commented on the stock anti-roll bar mounts.

Although, we have experienced no noticeable problems so far, Woodford has seen the stock

mounts crack and break under hard driving conditions (on the racetrack). An examination of

the mounts revealed surprisingly flimsy construction. The solution: A strengthened

anti-roll bar mount. Of course, AWR offers many suspension upgrades, including the

reinforced mount made from 4130 chrome-moly steel. Installation took a few minutes once

the bars were unbolted and dropped. By late afternoon, we thanked Woodford for his help

and began our 350-mile migration back to Northern California. Did the upgrades make a

difference? Keep reading...

While the car was on jack stands, Woodford commented on the stock anti-roll bar mounts.

Although, we have experienced no noticeable problems so far, Woodford has seen the stock

mounts crack and break under hard driving conditions (on the racetrack). An examination of

the mounts revealed surprisingly flimsy construction. The solution: A strengthened

anti-roll bar mount. Of course, AWR offers many suspension upgrades, including the

reinforced mount made from 4130 chrome-moly steel. Installation took a few minutes once

the bars were unbolted and dropped. By late afternoon, we thanked Woodford for his help

and began our 350-mile migration back to Northern California. Did the upgrades make a

difference? Keep reading...

Back to Thunderhill Raceway

We visit this wonderful track so often, perhaps we should pitch a tent in a paddocks and

live there. Thunderhill demands far more out of brakes and cooling systems than even the

most aggressive street driving or autocross. During just one brief lap of the raceway's

popular East Loop, the RX-7 was forced to threshold brake from 110 mph (at the end of the

long straight) to approximately 40 mph, then accelerate under wide-open throttle back up to

nearly 100 mph just before threshold braking for the hairpin at Turn 2. Turn 5 (the

"Cyclone") was another heavy braking zone that brought speeds down to almost a crawl

before turning sharp left and descending down an off-camber, left-hander. Turn 7 was

another heavy braking zone just before the sharp 20 mph left-hand hairpin leading toward

the long straight. One lap of the track with an experienced driver will, without a doubt,

make anyone appreciate the importance of serious brakes and a good cooling system. So how

did Project RX-7's brakes handle the heat? Beautifully. With a firm pedal and almost no

travel, Cooltech's upgrade is quite a revelation. Did I mention the pedal is firm? The

brakes provide alarming levels of decellerative force time and time again. Passengers will

complain of shoulder belts digging into their chests. Driver's will get a God complex once

they develop the confidence to push the system to its limits. Cooltech's research and

racetrack experiences paid off in spades. After a full session of hard driving (15 laps),

we experienced no brake failures and only minor fade which only occurred toward the end

of the session. By comparison, the stock brakes completely faded within two laps, while

the stock brakes using Hawk HPS pads lasted roughly four laps before fade became an issue.

Heel/toe footwork was far easier since the brake pedal refused to "mush" to the floor during hard braking. In fact, under all ranges of leg effort, the pedal would only sink 1-inch before hitting a "brick wall." After that, braking could easily be modulated with changes in pedal pressure, not pedal travel. Those who have driven real race cars will certainly appreciate the brake feel. With these wonderful characteristics, threshold braking without engaging the ABS system takes very little mental effort. After a few laps of getting used to the braking characteristics, it becomes completely natural--almost telepathic.

The combination of the lighter brakes and the upgraded front anti-roll bar mounts improved handling dramatically. The differences were not only subjective. In some respects, the changes were truly obvious. Turn-in response was improved and steady-state cornering became more confidence inspiring. Body control improved greatly during back-and-forth slalom-like maneuvers. The car felt more tight, refined, and responsive. To say we liked the changes would be a gross understatement. We could not find one problem with the performance improvements. Except maybe the faster response of the steering with mild inputs. While this trait may require a bit more concentration on the driver's part, we do not consider it a compromise--in fact, we like it that way. Brain fade will not be tolerated.

If you haven't guessed by now, the radiator worked flawlessly. At no time did the temperature creep above the normal position of slightly below the half-way point. In fact, even after a full session of non-stop, full-throttle driving, we noticed absolutely no signs of the engine running hot. We will have a water temperature gauge installed by the next installment to get some real readings. So far, the results are extremely promising.

Conclusion

The first round of performance upgrades has been a resounding success. Perhaps we should

stop while we're ahead. Rubbish. Let's keep climbing the magical mountain of mechanical

bliss. Let's cross that vast valley of vehicular vanity. Let us pursue and pontificate

performance, and all the joys it brings. Let us... aww... shucks, you get the idea. In the

next installment, we will subject Project RX-7 to suspension work as well as a host of

power enhancing goodies from Mostly Mazda's "M2" line of race-inspired performance upgrades.

Stay tuned...

SCC Editor's Note: For a comprehensive comparision test of various high-performance brake pads, refer the "Power Pads" feature in the November 1998 issue of SCC.

Sources Cooltech 15216 Mansel Ave. Lawndale, CA 90260 (310) 219-2888 Mostly Mazda 2111 Freemont Street Concord, CA 94520 (925) 686-9047 Thunderhill Park 5250 Hwy 162 Willows, CA 95988 (530) 934-5588

[Mail me] [To Lightning home] [To my home page] [Copyright Notice]