Date: Fri, 16 Mar 2001 16:59:17 -0800 (PST)

From: Ted Koseki (f8ldzz@yahoo.com)

Subject: RE: (rx7)[3] Rebuilding engine

Starting with an FD, you've got a more complex engine (and turbo) control system, so you got tons of wiring harness plugs and vacuum hoses you need to keep track of (i.e. labelling). Once the engine is stripped down to the short block, it comes apart and rebuild like almost any 13B motor.

The hardest part is getting all the parts sparkling clean (carbon deposits are not the easiest to remove!) and checking tolerances. At the same time, since you're reusing your old engine parts, you need to keep track of which seals came out of which hole/groove.

The downside to this whole project is if you actually threw out an apex seal (as Jeff mentioned) or cracked the water jacket - this necessitates spending a lot more money for housings!

The Mazda factory service manual is a must for all tolerances and torque specs on fasteners.

I'd recommend tackling a rebuilt to those looking for a good challange. In the end it's a pretty satisfying experience knowing you've rebuilt YOUR engine by YOURSELF!

The downside? Most of the pieces needed for the rebuild has to come from Mazda. Grabbing a "seal kit" (i.e. Mazdatrix) and "gasket kit" is going to break $1,000 right there. The deal with Malloy Mazda for <$2,000 short block is nothing short of a deal if you run it strictly by the numbers...

______________

Date: Fri, 16 Mar 2001 21:18:34 -0800 (PST)

From: Ted Koseki (f8ldzz@yahoo.com)

> But as Ted said, it's not really worth it when I have to spend $1,000 > in gaskets, I was hoping it would be closer to $500.

As a consolation, BEST case scenarios IF all these parts are in good condition:

This leaves the follow parts that NEED to be replaced:

This actually ends up costing within $500...

_______________

Date: Thu, 24 Jun 1999 11:15:41 -0500

From: jelkil@interaccess.com

Subject: (rx7) eccentric shaft nut size

54mm = 2-1/8", most of which are 1" drive, so you'll need an adapter.

______________

Date: Wed, 7 Jun 2000 17:09:31 -0500

From: "David Canitz" (dcanitz@royalpurple.com)

Subject: RE: (rx7) [all] breakin of engines with synthetics

Break in of new engines is a function of many variables some of which are:

Engines can be broken in on synthetics but generally on not because: during the assembly and initial break in period(scuffing / seating of rings to cylinder bore) contamination and wear particles will be generated. Most people will want to drain this contamination out with the initial oil change and not want to consider the possibility of normal drain intervals or extended drains.

However, I personally know of at least several Winston Cup teams that build engines and fire them up on the engine dyno using synthetics from the get go. What is different? They generally are using Total Seal piston rings which do not require the scuffing or seating to occur with the cylinder walls to seal.

Restating, if an engine builder wants some 'mating' of sealing surfaces to occur, then my recommendation is to use a quality mineral oil product for the break in period. At that point, usually 3-5 cycles on an engine dyno or 1500 - 3000 miles of street driving, the engines are ready to go. Change to the oil of your choice and down the road you go.

In the case of the Corvette, I believe the factory synthetic fill started when the engines where manufactured at OMC (boat builder) in Fondulac, WI. The all aluminum block was of significantly higher tolerances than normally found at GM that in most cases, significant blowby does not occur during the breakin period.

The worst thing that can happen with excessive blowby in an engine is 'glazing' of the cylinders. If this happens there is usually only two options. Tear down the engine and rehone the hard glazing from the cylinder walls or use an old drag racing / circle track trick and add Bon Ami cleanser to the old to try and knock the glazing off of the cylinder walls.

(Ed.'s note: this may also take off nice smooth surface from bearings, cam lobes, valve guides, etc. (assuming a real engine needed such things as con rods, valces, etc. :-))

Marc, if you are unhappy with the oil consumption, replace the Mobil 1 with a GM 4718 approved 10W30 mineral oil for 1500 miles and the rings would come in. Then return to the oil of your choice.

Royal Purple is used by Jon Ligenfelter in his ProStock Truck. (Marc know who that is.) We have a 5w30 or 10W30 that meets your warranty requirements for the vette.

By the way, I normally recommend use of the a mineral oil to breakin an engine Although on my 12A bridgeport I started with a synthetic from the second firing. I didn't want wear occurring on the seals. It ran 2 1/2 years (35 race hours) until I lost the rear bearing due to over revving while the tranny was stuck in 3rd gear at mid Ohio during the final 3 laps of the runoffs. It was a used rotor / bearing from a street engine. I was running 11 th at the time in an old Rx3 in GT3. (flying brick!!!)

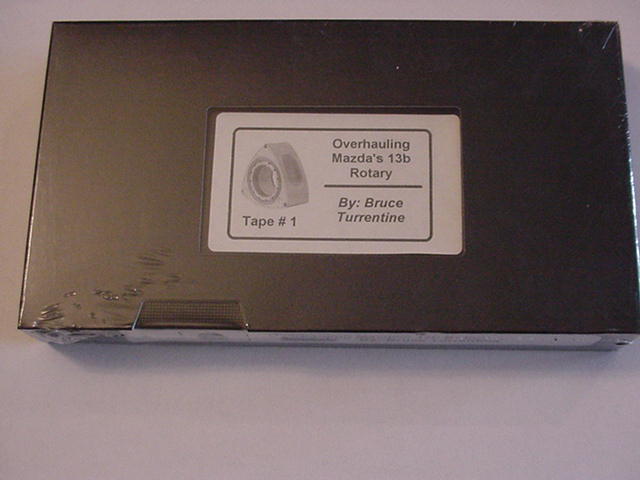

Date: Tue, 20 Apr 1999 15:21:57 -0500 13B engine rebuild tape, 2nd edition, Bruce Terrentine's.

Worth it's weight in gold. Best engine rebuild tape I have seen. You could

go out and rebuild your own just from this. I saw his first edition, this

one (2nd edition) is much better. You can't hurt yourself for ordering it

and educating yourself.

Contact Turrbie@aol.com for the latest price and availability...!

__________________

Bruce Turrentine's Instructional Video: - OR -

Order from: Cost is $29.95 (including priority air shipping).

__________________

Date: Thu, 8 Jun 2000 06:22:42 -0500 Bruce Turrentine 919-212-00 or 0671, (I can't read my own writing) makes a

great video on rebuilding the rotary.

__________________

Also see: http://www.rotaryaviation.com/video.html

From: root@albatross.prod.itd.earthlink.net Looks like the second try on the Teflon coated silicon "O" rings from

McMaster Carr was successful.

The part number is 9319K239. The Teflon-Encapsulated Silicone O-ring is

AS568A Dash No. 175 for $9.94 each. I received the one I ordered and

compared it to the Hayes and I can not tell any difference. The Dia is 9"

and the thickness is 3/32" and it lays in the groove just like the Hayes

meaning you have to work it a bit to get it to stay in the groove and a

little Hylomar to make it stick there.

So this is a price savings of $15.06 per ring or a $60.24 savings for a set

of four over the Hayes O rings. Thanks for pointing to the McMaster site

for "O" rings.

The web address is http://www.mcmaster.com

Date: Tue, 23 Dec 1997 18:19:08 -0800 (PST) Yesterday I stopped by Hayes to buy a set of Oil control rings and Oil O

rings for my dad for x-mas (SHHH don't tell him :), and had a chance to

voice some questions I have been getting from people interested in the O

rings, and oil control rings, but not wanting to try and piece together a

rebuild kit.

Don said he was willing to put together made to order rebuild kits for

list members. An example would be the factory gasket set. If you are

putting in the Hayes inner coolant O-ring, then you have no need for the

OEM inner coolant o-ring which comes with the gasket kit, and is a

healthy part of the cost.

He quickly jotted down on a piece of paper essentially what the minimal

rebuild should consist of. Its likely that its not totally complete as the

phone was ringing constantly as he was writing it, and answering phone

calls.

Anyone putting an engine together with single piece 3mm Ianetti seals

would have a more simplified list.

A later update from Trev's old web site:

If you are rebuilding a third gen engine, you will want most of what is below. Note the apex seal set is $1770, and that is for 3mm 2 piece Iananetti ceramic apex seals, which is a good idea if you like to run high boost. The corner seals are from an 85 GSL-SE, and are the solid type, so they won't break on you like the type with the rubber insert.

Rebuild Instructional Video

From: marc (cardmarc@concentric.net)

"Overhauling Mazda's 13B Rotary"

Now Available from Real World Solutions

Bruce Turrentine

5337 Trestlewood Ln.

Raleigh, NC 27610

From: jelkil@interaccess.com

O-rings

Sent: Tuesday, November 14, 2000 6:09 PM

Subject: High Performance "O" rings - Success!!!!

Rebuild Kit, Gaskets, etc.

From: NetBlazer (netb@world.bc.ca)

6 apex seals

6 apex seal springs (12 for 86+ 2mm seals)

1 engine gasket set

12 side seals

12 side seal springs

12 corner seals (I think this should be 6)

12 corner seal springs

8 oil seals

8 oil seal o-rings

8 oil seal springs (note you can substitute competition ones)

1 front main seal

1 rear main seal

1 thermopellet 86+

| 1 | Oil Filter | B6Y1-14-302 |

| 1 | Metal Upper intake manifold gasket: | N3A1-13-112 |

| 1 | Metal Lower intake manifold gasket: | N3A1-13-111A |

| 1 | Oil pan gasket: | N3YA-10-427 |

| 1 | Pressure neck with cap | N326-15-17YA |

| 4 | Turbo compressor inlet/outlet gasket | N3A1-13-712 |

| 4 | Turbo oil return pipe gasket Type 1 | N3A1-14-293 |

| 1 | Turbo oil return pipe gasket Type 2 | N3A2-14-293 |

| 9 | 10mm nut (downpipe to turbo and turbo to exhaust manifold) | JE10-40-355 |

| 9 | 10mm stud (downpipe to turbo and turbo to exhaust manifold) | NF01-13-708A |

| 1 | 8mm nut (turbo to exhaust manifold) | E5B6-13-461B |

| 1 | 8mm stud (turbo to exhaust manifold) | N391-13-456 |

| 4 | Large 10mm nut (Exhaust manifold to rotor housing) | 9YB1-01-0010 |

| 4 | Large 10mm stud (Exhaust manifold to rotor housing) | 9YA9-21-0020 |

| 1 | Waterpump to housing gasket | N3A1-15-116 |

| 1 | Waterpump housing to front housing gasket | N386-15-162 |

| 1 | Metering Oil Pump O ring | N350-14-604 |

| 1 | Thermostat Set | 8AF5-15-171 |

| 1 | Front Rotor (13B TT) | N3YA-11-B10 |

| 1 | Front Rotor Housing (13B TT) | N3A1-10-B10 |

| 1 | Front Cover Gasket | N3A1-10-502 |

| 1 | Front Cover O-Ring | N231-10-174 |

| 1 | Front Main Seal (13B TT) | N3A1-10-507 |

| 1 | Rear Main Seal (All) | 1668-10-556A |

| 2 | Comp Oil Seal Spring (Front/Outer) | 4352-11-353 |

| 2 | Oil Seal Spring (Front/Inner) | N225-11-351 |

| 2 | Comp Oil Seal Spring (Rear/Outer) | 1011-11-363A |

| 2 | Oil Seal Spring (Rear/Inner) | N225-11-361 |

| 1 | 3mm 2 piece Ianetti Apex Seals (set of 6) | 0000-01-9115 |

| 12 | Apex Seal Spring | 1757-11-304 |

| 12 | Solid Corner Seal | 1011-11-321 |

| 12 | Corner Seal Spring | NF01-11-C24 |

| 12 | Side Seal | N3Y1-11-C11 |

| 12 | Side Seal Spring | NF01-11-C17 |

| 1 | Throttle Body To Upper Intake Gasket (Metal) | N3A1-13-655 |

| 4 | Outer Coolant Seals | N326-10-B72 |

| 2 | 850cc Fuel Injector | N3A2-13-250 |

_______________

Date: Thu, 28 Jun 2001 21:05:35 -0400 (EDT)

From: Shane Baker (sbaker@null.net)

Subject: Re: (rx7)[3] gaskets needed for changing engine?

I saw someone mention a reman gasket set about a week ago. I don't know if something like that exists, they may have put together such a package.

If not, I will try to be complete (note that some gaskets that the manual says that you need I am not listing because you very rarely need to replace them - e.g. the exhaust manifold gaskets). I'm posting this public so that, hopefully, and missing gaskets will be caught.

Copper washers:

4 for the oil cooler lines (banjo bolts) 8 for the turbo coolant lines 4 for the turbo oil feed lines 4 for the MOP lines at the injectors 4 for the MOP lines at the MOP 2 for the secondary fuel rail

Rubber O-rings

You should have new ones in the engine for the primary injectors (IIRC) You might want to replace the secondary O-rings You might need an intake elbow to TB gasket. 1 for the MOP 2 for the oil filter neck 1 for the oil filler neck

Other gaskets

Unless you have started with a 95 model (or already have a metal one) you will want to replace the lower intake gasket. 1 for the air injection line out of the back of the engine to the cat (for some reason, that one's paper) The rest of the gaskets (that I can think of) are metal and should be reusable. You might want to change the turbo oil return gaskets anyway, on mine they were pretty well crushed and the prospect of not changing them and having a problem later was not pretty.

Other things you may need:

New exhaust manifold nuts New DP / precat nuts.

Part numbers I can't help you with (I might be able to get some of them if you REALLY need them, I still have the plastic bags that some of them came in... somewhere).

I'm sure I missed a couple, but that should be close to everything. If you have done anything like disconnect the P/S, you might need washers for that, I don't know. Also consider (if you haven't already) getting a set of new coolant lines. Some of them are not easy to get to, generally, and you might as well change them now.

I assume that you'll also want (again, if you haven't already) to replace your vacuum hoses.

One of your biggest problems is likely to be the wiring harness. They do get very brittle. I bought a new one, not cheap, but I really didn't want to worry about troubleshooting electical problems after I was done.

________________

Date: Sat, 31 Mar 2001 13:45:05 -0800

From: Sonny Yeoh (syeoh@bravidacorp.com)

The aluminum side housings exist, and Racing Beat carries them.

From their catalog:

"Flame Sprayed Aluminum Side Housings: We offer a series of Aircraft Grade A356 aluminuum alloy side housings to replace many of the heavier, cast iron stock assemblies found on all 1974 and later 12A, 13B, 20B and 13G engines. Our housings offer both the obvious advantage of significant weight savings and greatly increased wear resistance, even under high horsepower demands......

As an example of the significant weight savings: a stock, intermediate housing on a 1993 13B turbo engine weighs 25.9lbs, while the RB aluminum replacement weighs just 10.5lbs... the stock rear housing on the same engine weighs 25.8lbs, while the RB aluminum replacement weighs just 13lbs....

After each aluminum housing is cast, using A356 Aircraft Alloy, it is heat treated to "T-6" hardness then CNC-machined prior to being flame-sprayed and ground to a final finish. The greatly increased wear resistance is the result of this aerospace originated flame spray (or plasma spray) process that imbeds into the wear surfaces a proprietary carbide material whose durability greatly exceeds that of the nitride surface.... it was not uncommon to find no measurable wear on these housings. We have found the flame spraying process to be so effective that we utilize the process on stock side housings with the same excellent results...."

They list part numbers for the FD as 11051 (front housing), 11061 (intermediate housing) and 11071 (rear housing). Their price list, however, lists a "call" price on the front and rear housings, and $1900 for the intermediate housing. BTW, they list these housings are cast for a peri-port engine; in the pictures there is an outline for the side intake port, but it is plugged - so a port job may be required as well.

_______________

Date: Tue, 10 Apr 2001 19:55:03 -0700

From: "Max Cooper" You can also eliminate this piece and save some money if you are replacing

the eccentric shaft anyway by using one from an older engine.

_______________

From: Carlos Iglesias When rebuilding or merely resealing a engine component,

the best sealant is Mazda's Gasket Sealant, P/N 8527-77-739.

Be advised, the best is never cheap: standard size tube is

$19.80 from Mazda Comp :-0

_______________

Date: Thu, 8 Oct 1998 22:34:13 -0400 Motor Mount (Left)

Left motor mounts (stretching) tend to tear by at least 50-60k miles. Every

rebuild which I've witnesses (6) has had mounts within this mileage or higher,

has had the same problem. Expect/budget to repair.

Left motor has been redesigned to include a retaining mechanism to correct this

design discrepancy. Be sure that part number ends in "A" or subsequent.

Additionally, Mazda Comp has competition motor mounts with 40% hard rubber which

are described as more durable.

________________

Date: Thu, 8 Oct 1998 22:43:24 -0400 13B Front and Rear Rotor Housings

The only difference between Front (N3A1-10-B10) and rear (N3A1-10-B50) rotor

housings is which side the EGR channel comes in from. Because of this, non-EGR

critical applications may interchange the parts.

________________

Date: Thu, 8 Oct 1998 23:17:05 -0400 Anti-Seize

Finally found an anti-seize which will stand up to the extreme temps of a

rotary: Fel-Pro HD Anti-seize (http://www.chemical.felpro.com/antiseiz.html) is

rated at 2400F.

Now if I can just find somewhere to buy the nuclear grade Hi-Performance N-5000

Anti-Seize ;-)

_________________

Date: Fri, 9 Oct 1998 13:45:32 -0700 Just so happens that I work at a nuclear plant, and as a Materials Engineer.

We use lots of the FEL-PRO Nickel Graphite Lubricant N5000. It's available

in 1lb containers (p/n 51269) for around $30. It's also available in 1oz

tubes (p/n 51346), although that may be the p/n for a case of 48 tubes. The

case price is around $250. You may be able to buy just 1 tube, which would

equate to around $5.

It's available from either of the following companies, or you can call

Federal Mogul's (formerly FEL-PRO) customer service department @

(800)480-1212 to find a local distributer.

Industrial Specialty Products (or)

Applied Industrial Technologies [Mail me]

[To Lightning home]

[To my home page]

[Copyright Notice]

> I know there was a place/shop out there selling a oil bypass eliminator

> that you replace the oil bypass valve in the eccentric shaft under the front

> pulley bolt so that the oil pressure didn't drop during warm up, but i can

> seem to find them/ where that was.

>/PRE>

Mazdatrix has them (part #11-PLUG)

Date: September 27, 1998

From: rotary@mediaone.net

From: rotary@mediaone.net

From: rotary@mediaone.net

From: "Kinports, Robert"

(562)806-2600

(805)928-1863