Date: Thu, 12 Mar 1998 20:24:11 -0500

From: Felix Miata (mrmazda@gate.net)

Ratios of the five forward speeds of a 3rd gen:

1 - 3.483 2 - 2.015 3 - 1.391 4 - 1.000 5 - 0.806 R - 3.288

______________

Date: Thu, 12 Mar 1998 21:46:23 -0600

From: "Steven F. O'Sheal" (sosheal@voyageronline.net)

The workshop manual is a little different. It lists (page J-3)5th gear as 0.719. However, the Service Highlights agrees with Felix (page J-2).

______________

From: Orin (OrinMllr@aol.com) Date: Tue, 07 Mar 2000 22:18:19 -0500 Options:

Can one of the Greddy dealers ask Gredyy about the Quaife kit? I believe

the other 6-speed conversion kits in Japan are realatively inexpensive,

either $1800 or about $3000, don't remember which.

_________________

Date: Tue, 07 Mar 2000 21:38:12 -0600 Has anyone actually seen the power handling specs on the Miata/Toyota six speed?

The last I heard everyone was "presuming" it didn't have the capacities, but I

have been told by a RX7 shop it is a direct bolt up and would definitely handle

stock power and a little more, but I have yet to be able to find any concrete

evidence of what the tranny is capable of.

_________________

Date: Sat, 31 Jan 1998 10:14:59 -0800 Yes, there is one in Japan. A company named TFR makes 5- and

6-speed transmissions for both the FC (2nd) and FD (3rd).

The FD 6-speed is about $8k.

__________________

Date: Mon, 7 Feb 2000 10:00:19 -0800 (PST) This is a six speed dog-ring conversion which utilizes

the standard gearbox casing. The person I spoke to

said that he believes it was developed for the third

gen RX-7. However, it is manufactured for Trust

(Greddy) in Japan, and as a result they have exclusive

rights to sell it. I did not get a price for it. I

guess I'll have to call and see if Greddy could get a

set from Japan. I have a feeling it will be cost

prohibitive, however :)

Maybe it would just be better to get a racing

six-speed sequential box (Quaife, X-Trac and others

have these) and have a custom bellhousing fabricated,

anyone have some (significant) money to burn??

___________________

Date: Wed, 22 Mar 2000 22:02:29 -0500 Guys, I thought this might be of some interest to some of you. its from

quaife usa on their 6 spds for the 3rd gen. -gordon

A lot of people wrote saying that the Mazdaspeed is the one to get. I didn't save any

of those posts, however. I got mine from Rotary Peformance (Dallas), but Corksport was

also suggested as a place to get it. --Steve

____________________

Date: Wed, 17 Mar 1999 13:18:30 -0700 I've tried both the C's short shifter as well as the Mazdaspeed short shifter. From my

experiences, the Mazdaspeed is better. All the C's shifters I've tried feel notchy,

"clicky" and sometimes damn hard to get into gear. Same goes for the C's shifter for

Miata applications. The Mazdaspeed unit is far better-- just as smooth as stock.

Both shifters have similarly narrow gates. I'll be using the Mazdaspeed shifter for

Project rx7. I think the C's is cheaper, but the Mazdaspeed is definately worth the price

of admission, imho.

____________________

Date: Wed, 10 Jun 1998 10:42:23 -0400 I have the C's Short shifter and so do several other members as I recall. The quality and

fitment are great, and it is a very robust unit. Install is simple and the new shortness is

great. Pull is a bit harder and emphasizes the bad synchro in 5th gear, but this is true of

all the short shifters I believe.

I got the best deal on it at NOPI, and it isn't cheap. Good

news is, Pettit's cost more and to order from Rotary Performance it is also more money. Go to

www.nopi.com and you can also get a 5% discount if you mention their add.

___________________

Date: Wed, 10 Jun 1998 11:38:53 -0400 I also have the C's short shifter in my 88 GXL. Very nice piece of hardware. It cost me 266$

but it was worth the money. Installed in 10 minutes and REALLY shortens the throw. Does make

it harder though in terms of pull but nothing horrible.

___________________

Date: Sat, 16 Jun 2001 13:27:08 -0400 I love my B&M shifter. It included the shift lever *and* base. You can buy

it at [http://www.summitracing.com] for $179 + handling, part # BMM-45083.

___________________

Mazdatrix is supposed to have a new short shifter out for the 3rd gen. Will post

info when I get it. --Steve

___________________

Date: Wed, 09 Feb 2000 02:21:04 -0500 I just got my Mazdatrix short shifter in the mail and promptly installed

it on my '93 RX-7. I had heard from Mazdatrix that some customers were

reporting noise problems, so I've been waiting to order it for a little

while now.

Installation was a breeze, although the documentation wasn't the best, it

was easy to figure out by applying a bit of logic. All new bushings and

seals are included as well as a whole new shaft. Build quality was

excellent and everything fit properly into place. Getting to the panel is

incredibly easy. Most cars are a pain to change shifters in, but the RX

has that nice removable center console panel. I finished the install in

about 20 minutes.

First impressions? Shifting effort is much greater, perhaps because all

of the bushings are brand new. I also chose to use both of the supplied

shims instead of just one, so that may impact it some. The throw is VERY

short and the motion extremely precise. The distance between gears from

left to right is reduced as well as the forward to backward throw, so it

takes a bit of getting used to. I had a problem with grinding going into

second which I suspected was actually gear wear or synchro wear from a

previous owner. With the new shifter, all shifts are smooth, no more

problem! This made me happy.

I didn't encounter any noise problems as others have apparently reported.

My tranny has 100,000 miles on it and has no 5th gear synchro problem. I

can detect no additional vibration or noise from the shifter over the

stock one. Shifter movement is much more precise than stock and the gates

feel much cleaner on shifts.

I also took this chance to modify the length of the shift lever to

accomodate a shift knob from a Mazda Miata. The "Voodoo Bob Knob" that

was created by one of the Miata list members is the exact same thread

pattern as the RX-7, but is designed to mount lower on the shift lever. I

simply ground 1/4" off of the threading and used a nut that was put on to

measure the amount of grinding to rethread the first thread. The knob

went on smoothly and sits flush against the tapered portion of the shift

lever. This reduces the throw further, but I like the look of the knob.

They're also $32 compared to $80 for the Momo knob I liked. This one was

free, since I pulled it from my previous car.

So far, with somewhat limited driving time, I really like the feel of the

short shifter. The tranny feels more precise and my second gear crunch is

gone. Since I'm used to a short throw Miata transmission, this mod makes

me a lot happier with the RX-7. For $200, in comparison to more expensive

short shifter kits, I find the Mazdatrix kit to be outstanding. Note that

I'm not comparing the others, since I haven't driven a car with any other

the other kits, but I find the Mazdatrix kit to be well built and very

functional as well as having the best price.

_______________

Date: Sat, 4 Apr 1998 10:32:41 -0500 I shortened my shifter by about 1/2 inch by installing a Sparco aluminum

ball shift knob, modifying the shifter's mounting sleeve and grinding about

1/4 inch off the shifter shaft. The aluminum shift knob lets you feel the

shifts more than the stock leather covered and lead-weighted knob and I

like the shorter shift throw. The polished aluminum Sparco ball shift knob

was $35 and its shaft hole is as deep as it possibly can so it will mount

lower than the stock knob.

The stock shift knob comes off simply by unscrewing it (turn it

counterclockwise), there is no lock screw to hold it on. Most aftermarket

shift knobs come with plastic sleeves that adapt the hole in the shift knob

to the shaft size. You want to use the adapter that fits snugly and will

screw down onto the shaft.

You then want to cut off the "cap" of the sleeve

so you can screw the adapter down lower onto the shifter shaft. This will

allow the shift knob to go on deeper to the point that the shaft end

touches the knob. This mod alone will lower the Sparco shift knob more than

1/4 inch lower than stock.

I wanted to go a little lower so I mounted a 5

1/2-inch course grinding wheel on an electric drill and ground off about

1/4 inch of the shifter shaft. I cleaned up the beginning of the shaft

threads with a small file so I could still re-mount the stock shift knob if

I wanted to. After the grinding the bottom of the Sparco shift knob sits at

the shifter boot and looks great. I'm very happy with the way the shifter

works and feels.

I've got photos on my web site.

See the How To's/Short Shifter.

________________

Date: Tue, 22 Sep 1998 10:32:21 -0700 Shortening the shifter decreases the distance that your hand

has to travel... the arc of the top of the shifter, when travelling from

point A to point B, has been reduced in length. A true "short shifter" has

a mechanical advantage (increased length, I believe, below the fulcrum)

which moves the transmission into engagement more quickly. Shortening

the shifter results in a shortened "throw", but it's mostly psychological in

benefit. However, it is necessary, with some aftermarket shift knobs, to

shorten the shifter, and this is what I did.

If you're going to cut your shift lever, remember to thread on a bolt prior

to cutting it. After the cut, you can back the bolt off (after cleaning the

threads, if necessary, with a small file) and restore the threads. I removed

roughly 5/8" from mine, and decreased the shift throw while increasing

stereo clearance (very important...) with about 3 minutes of "work". Much

better, in my opinion, than spending $250 for a short shifter when I can

already shift the transmission much faster than it should be shifted. As

you all know (or should know), power shifting is not recommended...

______________

There was some discussion on one of the assorted message boards on using

the Miata shifter, since is is smaller. The concensus was that it will fit,

but that the lever arm is not any shorter. It will only stick up less-high

than the RX-7 shifter (i.e.- the throw will end up the same). So while it

will fit, it won't make any difference. --Steve

From: Steve Cirian (steve@ScuderiaCiriani.com) Various brands are available, including Racing Beat, Mazdatrix, Tri-Point,

Indigo, etc.

These typically require the use of the counterweight from the

automatic transmission. Make sure if you buy the lighter flywheel that

the counterweight is included, or you order it separately.

The new combination SHOULD have lower inertia than the stock unit, since

the counterweight is close to the center. So even if the combined weight

is not that much less than the stock flywheel, you will still be gaining

something.

Some of the aluminum flywheels have a steel (or iron?) insert that is

replaceable. If it is not (or even if it is), make sure you can have it

resurfaced next time you replace your clutch.

_______________

Date: Thu, 15 Feb 2001 23:52:26 -0500 By careful, tedious, 'compound pendulum' measurments, the inertia of the

flywheel, and clutch cover, can be determined. I just installed a RB steel

f-wheel. I had components weighed on a 2 decimal place, digital scale at a

'mail-box etcetera' place, and completed these inertia meas'ts and

calculations.

Weights:

The 'Inerta' value is "slug*in^2", where slug is a mass unit:

The fw and clutch cover are the main 2 inertia components to consider. For

the stock set-up, the fw is 68% of the pair total. The RB fw has 12.5% less

weight than stock, and 31% less inertia. It reduces the inertia of the stock

cover and fw pair by 21%. This can be felt in shifting, with a little freer

reving.

Could work with someone to check an aluminum fw too, for comparison. IF it

had 1/4 the sock fw inertia, the fw and cover pair inertia would be reduced

50%, for example.

_________________

Date: Fri, 16 Feb 2001 00:20:52 -0500 I don't see anything above to account for the average mass distance to

center of rotation. Just the auto counterweight alone can account for a

lot of the difference. A stock flywheel has the imbalance in the

periphery, while the whole counterweight is close to center. Stock

flywheels from earlier engines have a much higher average mass distance

from center. I have to believe there is little if any difference in this

characteristic for a 3 gen.

When light steel flywheels for rotaries were first introduced over 20

years ago, I remember reading somewhere that the net inertial reduction

was something on the order of 80%, and for aluminum over 90%.

__________________

Date: Fri, 16 Feb 2001 08:42:14 -0500 Equation was derived from inertia section of my old physics text, and

expanded using the parallel axis theorm .... twice in the case of offset

mass centers:

Jspin = m*g*L / (2*Pi*f)^2 - m*(L^2 - e^2)

The offset mass center of the cw and oem fw was accounted for with the

'e' term. Method is valid for small test displacements .. I used a knife

edge pivot, and about 1 or 2 degrees of sway.

ALL inertia values I listed are about the spin center. I listed the cw-only

inertia, but it is included in the .733 value for the RB steel wheel.

Date: Thu, 30 Jul 1998 10:22:50 -0400 (EDT) Magneti Marelli makes a retrofit sequential shifter that works with the

stock gearbox. It's basicly a set of actuators that shift when you tell it

to. No rev matching or any of that fancy stuff (isn't sequential shifting

fancy?) unless you buy the ECU. Price? Let just say the ECU is more

expensive than the Motec people have been complaining about. These guys

make F1 stuff. Phone number? 317.471.1559 TW Racing Components is the US

distributor.

_________________

Date: Thu, 30 Jul 1998 17:07:41 -0400 (EDT) Technically, "shift-by-wire servo-controlled gearbox ... for passenger car

market". Clutch and H-gate replaced by joystick or F1-style paddles. It

integrates gear and engine control so you don't have to match revs and you

can full-throttle shift. Consists of two actuators mounted directly on

the tranny controlling peddle travel and gear selection. Retains

conventional manual tranny benefits like low cost (yeah right) and weight,

robustness, and simplicity.

So basically. a couple of actuators that shift for you and presses the

clutch for you. I don't have the price. Call the US distributor.

__________________

Date: Thu, 16 Dec 1999 20:43:04 -0500 Try Hewland. They make sequential for almost any

application.

Is it possible to put syncros on a sequential box? I've never seen this. I

think, I'm not sure, the nature of sequential requires dogrings.

Quaife makes them too, but I do not know any specifics. I think the

address is Quaife.

On non-Japanese cars, the speedo sensor line (terminal 1M) on the ECU seems

to have two voltage levels which tell the ECU if the car is moving (2-3v) or

if it is stopped (4-5v). On Japanese cars it is also used to signal if the

car is going over 180kph and operates a fuel cut-off at that point. I don't

know what voltage it puts on the line (maybe 0v?) to operate the cutoff.

This is obviously not a straight connection to the speedo sensor on the

gearbox, since this is effectively a small electrical generator which

generates nothing when the car is stationary. There must be some

electronics between the sensor and terminal 1M

The odometer, speedometer and trip meters all operate from the speedo

sensor, and again there is some circuitry employed to generate a square-wave

input which triggers a complete pulse for every 18 inches or so that the car

travels. The Mazda spec is 8208 pulses per mile (5096 per km) which is half

the sinusoidal square-wave frequency that is generated by the speedo sensor

on the gearbox. The sensor sends 8 AC pulses for eac one turn of the driven

gear on the sensor. (Training manual page T-43)

You can use pulses per mile spec to calculate the input pulse rate (in

pulses per minute) required to indicate a selected speed using the following

formula:

Input Pulse Rate = (8208 * Selected Speed)/60

The training manual (page T-35) also says the following tolerances are

acceptable:

[Mail me]

[To Lightning home page]

[To my home page]

[Copyright Notice]

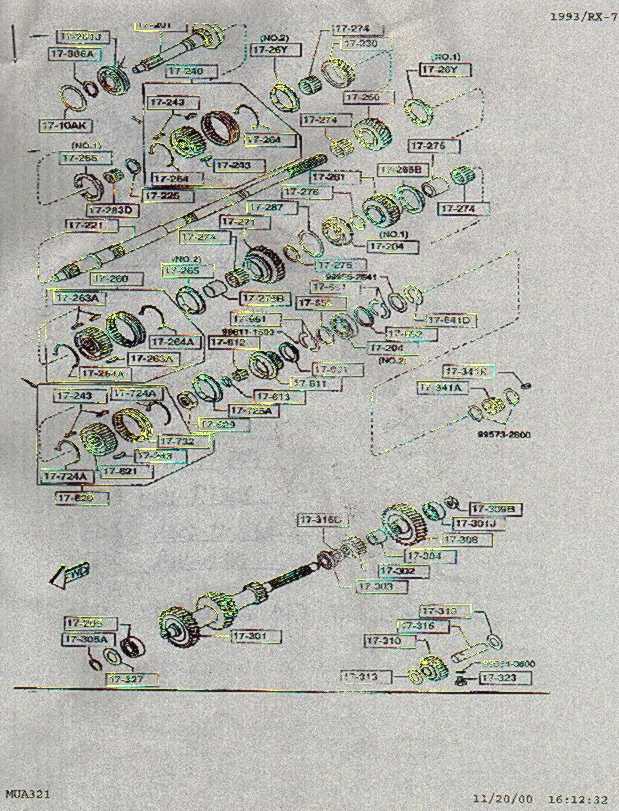

Transmission Diagrams

Date: November 22, 2000

6-speed Transmission

From: Stephan Lee (slee@titan.me.jhu.edu)

From: David Bennett (rx7x2@home.com)

From: Thi Nguyen (thi2@earthlink.net)

From: Mark Valskis (mvalskis@yahoo.com)

> Quaife makes a gear kit for the Mazda RX7 Turbo,

> they don't say if it is for the second or third

> gen. But it has 6-speeds and dog rings. I suspect

> it is for the 2nd gen though.

>

> They have a US distributor, Autotech Sport Tuning.

>

> I'm too busy during the week to call them. Anybody

> want to drop them a line? 949-240-4000. They are in

> San Juan Capistrano, CA

From: Gordon Monsen (gmonsen@fast.net)

> Thank you for your inquiry. Quaife manufactures 2 different types of RWD

> gearboxes. The first is a small GT car type gearbox that is capable of

> withstanding up to 300 bhp. The second unit is much larger, heavier and

> stronger and is designed for up to 650 bhp. The approximate cost would be

> about $15K with all of the accessories for the sequential shift version

> 6-speed.

>

> Since the gearbox is dog engagement, it is not necessary to use the clutch

> on the upshift but the revs must be matched on the downshift. This is an

> acquired skill that takes practice to master. Some of our customers who

> have never used a dog engagement gearbox report to us that it took them

> almost a full season to master the gearbox.

>

> The gearbox shifts much faster than your standard synchromesh gearbox. The

> difference is night and day!

>

> Regards,

>

> Ralph Hollack

> Director of Operations

Short Throw Shifter

From: "Shiv S. Pathak"

From: Rippin

From: JC Fedorczyk

From: "Firas Arabo" (firas_arabo@hotmail.com)

From: jules@learnlink.emory.edu (Sean P. Murphy)

Subject: (rx7) Mazdatrix Short Shifter Install

From: Rob Robinette

From: "Jim LaBreck (ECA)" (a-jimlab@microsoft.com)

Flywheel (incl. lightnened)

Date: May 14, 1998

From: "kevin kelleher" (kellehkj@earthlink.net)

Subject: (rx7) [3] RB Steel vs Stock Flywheel Inertia Numbers

From: Felix Miata (mrmazda@atlantic.net)

From: "kevin kelleher" (kellehkj@earthlink.net)

m = mass in slugs

L = distance from test pivot to cg, inches (predetermined by balance test)

f = sway frequency in cycles/sec

e = distance from cg to spin center, inches

g = 386.4 in/sec^2

Sequential Trans Conversion

From: Stephen J Lee

From: Stephen J Lee

From: Stephen J Lee (Stephen.Lee@jhu.edu)

Speedometer Sensor

Date: Wed, 19 Jan 2000 12:50:12 -0800

From: Stephen Stanley (sstanley@microsoft.com)

Veh Speed Input pulses/min Speedo indication

20 2,733 20-22

40 5,467 40-42

60 8,200 60-63

80 10,933 80-84

100 13,667 100-105

120 16,400 120-126

140 19,133 140-147

160 21,867 160-168

180 24,600 180-189